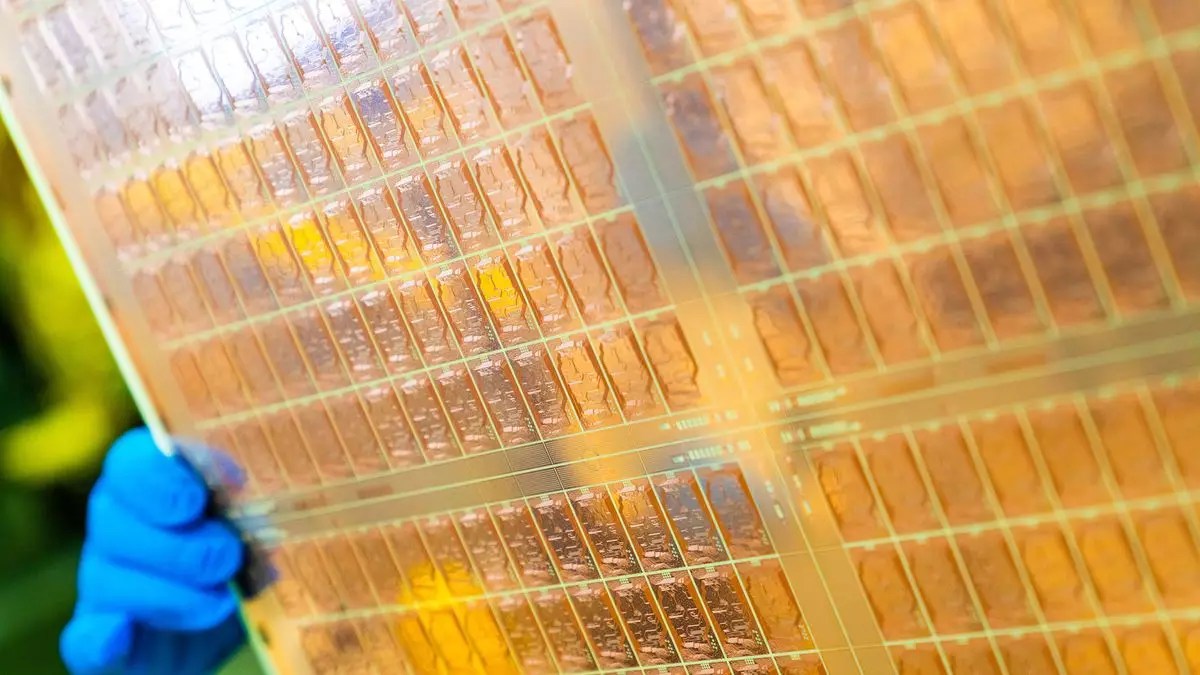

The world of chip and substrate fabrication may not sound thrilling to everyone, but advancements in this field can lead to significant performance and efficiency improvements. Recently, there has been a buzz surrounding the use of glass substrates in place of organic ones for chip-to-chiplet and chip-to-motherboard communication. This shift could bring about a range of benefits that could revolutionize semiconductor manufacturing.

Glass substrates offer a flatter and more durable surface compared to organic substrates. This characteristic allows for easier lithographic insertion of more densely packed interconnects, ultimately leading to higher interconnect density and faster IO. In addition, using glass substrates can result in higher power efficiency and the ability to accommodate larger package sizes. Companies like Intel have already recognized the advantages of glass substrates and are incorporating them into their future plans.

AMD, known for its Infinity Architecture that includes chiplet-to-chiplet and chip-to-motherboard interconnects, is also exploring the use of glass substrates. Reports indicate that AMD is evaluating glass substrate samples from major semiconductor substrate companies with the intention of introducing this advanced technology into its manufacturing processes. While this development is promising, it may take time for glass substrates to become widely adopted in the industry.

Both Samsung and Intel are making strides towards mass production of glass substrates, with targets set around 2025 or 2026. AMD could potentially leverage partnerships with these companies to realize its goal of introducing glass substrate chips to the market within the same timeframe. However, it is important to note that initial implementations of glass substrates may be limited to specialized products rather than mainstream desktop CPUs.

While chiplet designs are gaining popularity in the gaming processor market, the initial impact of glass substrates may be more significant in AI and HPC datacenters. AMD’s EPYC lineup, designed for high-performance computing, may benefit greatly from the use of glass substrates in its multi-chip packages. As the industry progresses towards adopting new fabrication technologies, it will be interesting to see how glass substrates shape the future of CPU designs.

The introduction of glass substrates in chip and substrate fabrication represents a significant technological advancement with the potential to improve performance and efficiency in semiconductor devices. While the timeline for widespread adoption of glass substrates may still be a few years away, the groundwork is being laid by industry leaders like AMD, Intel, and Samsung. As this shift unfolds, it will be essential for manufacturers to adapt to new fabrication techniques and explore the possibilities that glass substrates offer for enhancing semiconductor products. Stay tuned for more updates on this evolving technology landscape.

Leave a Reply